Design Considerations

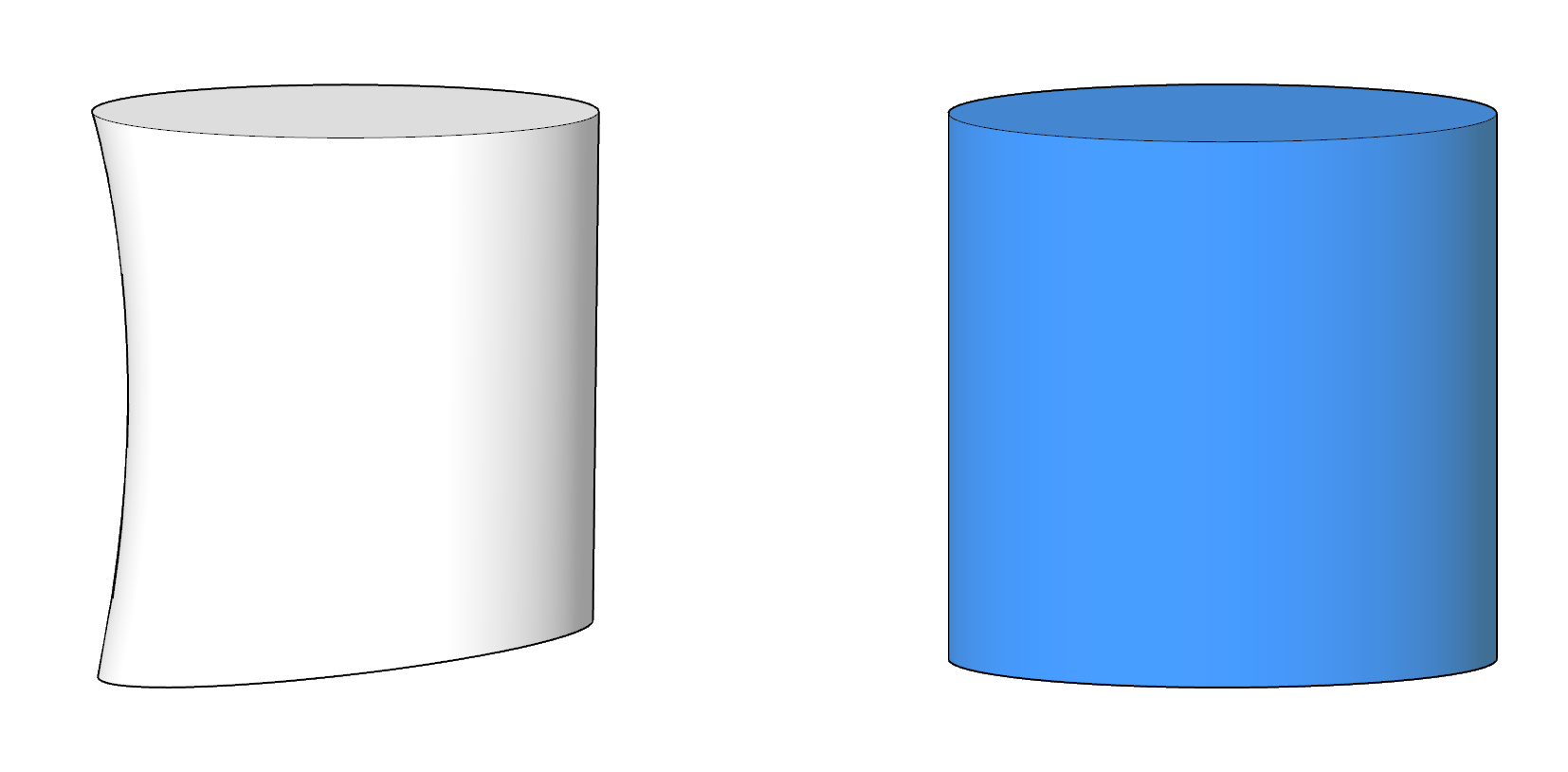

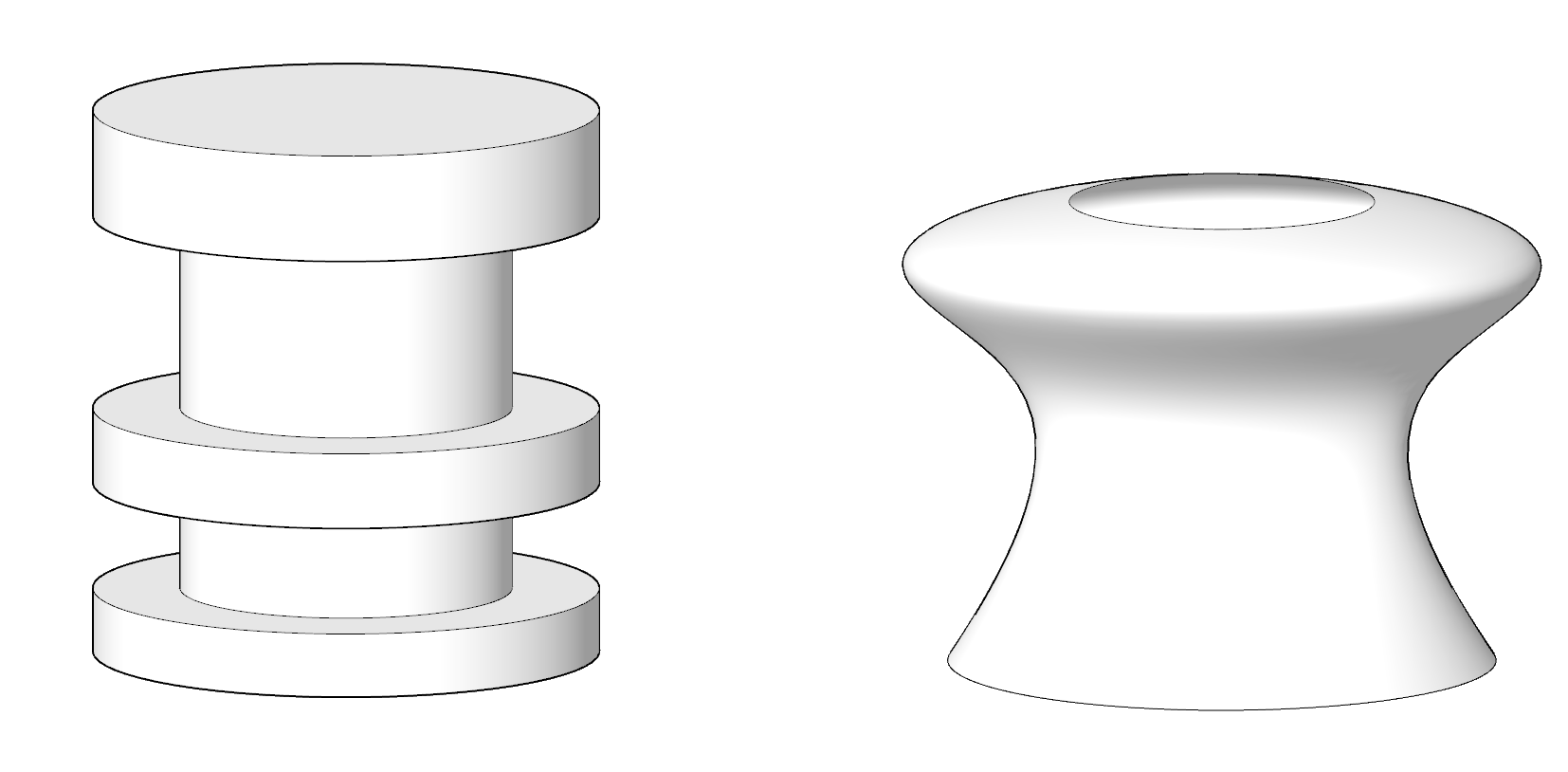

Foundational Layers

Ceramic printed objects should have a flat first layer to ensure a solid foundation for printing.

dFab recommends avoiding aggressive angles on the first few layers of a print as this will reduce the likelihood of deformation or collapse

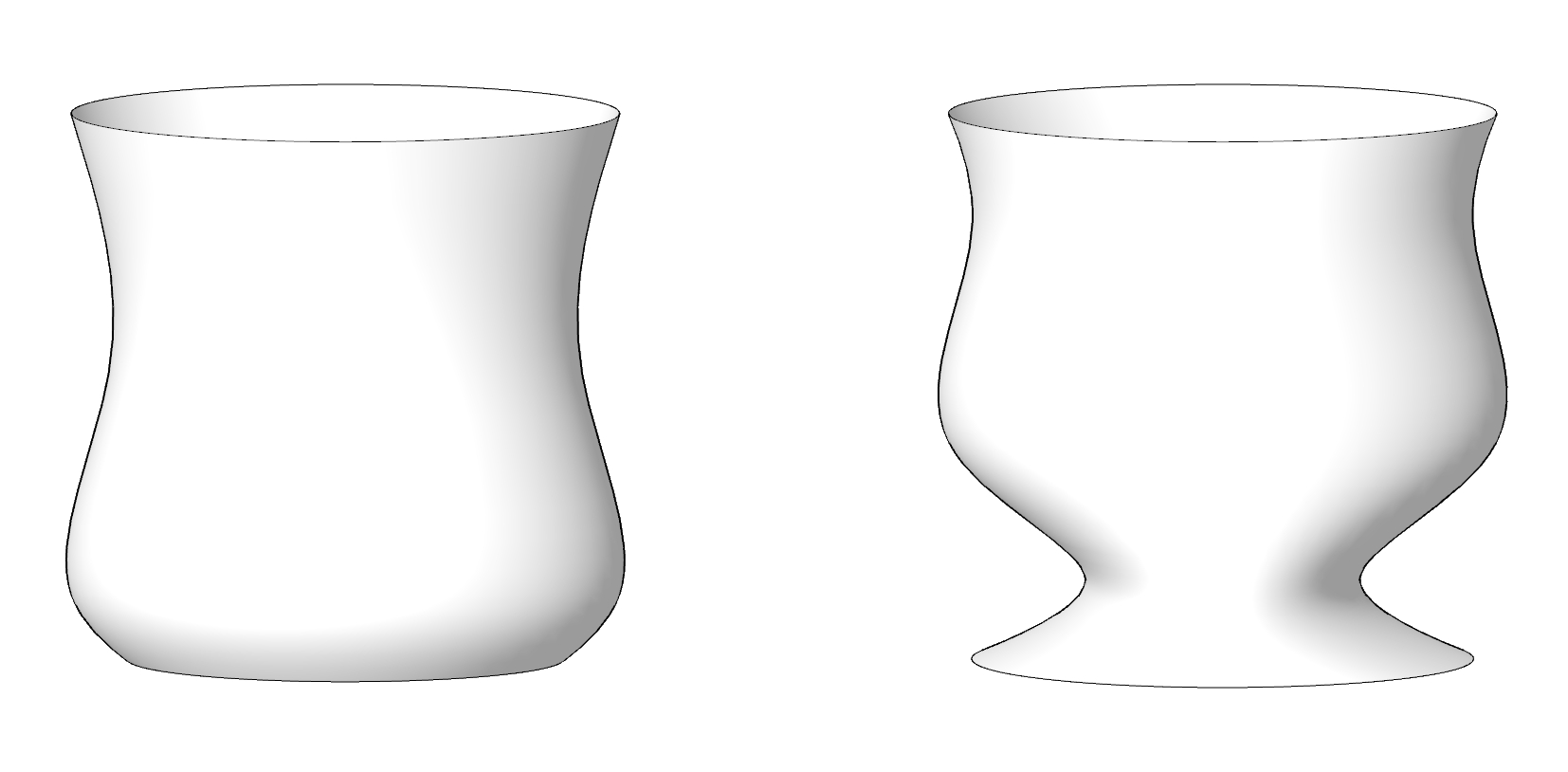

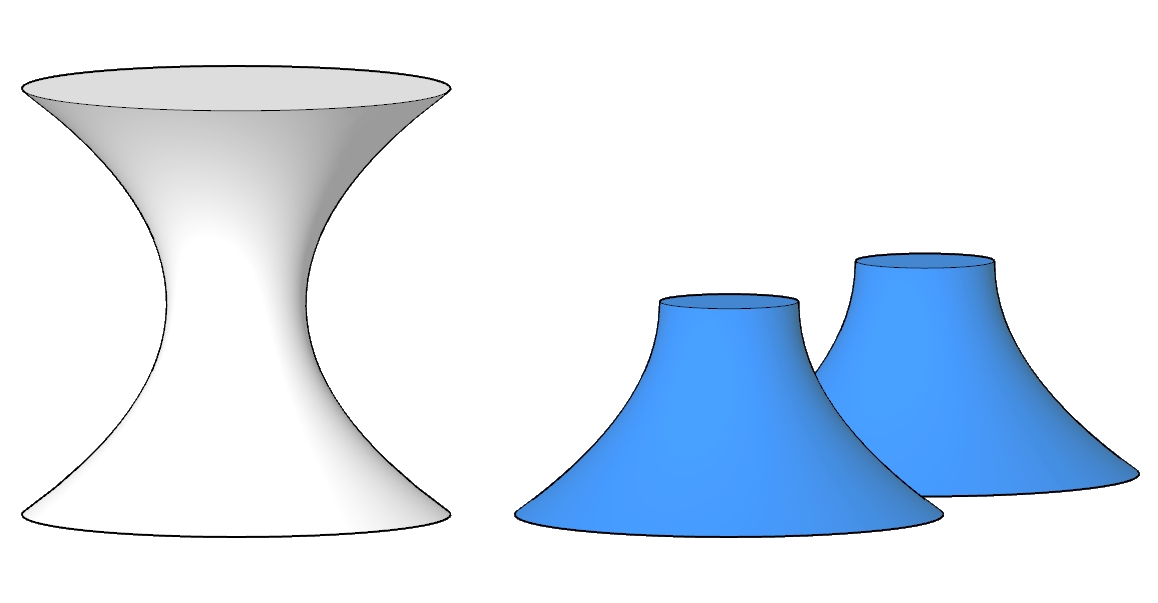

Overhangs

Ceramic printers are not capable of the unsupported overhangs achieved by FDM 3D Printers. Overhangs >30° & Unsupported geometry will cause the clay to droop and potentially collapse.

dFab recommends avoiding steep angles unless drooping or slumping is desired.

Slice settings (layer height, flow, etc) can be modified to improve a printers ability to achieve overhangs

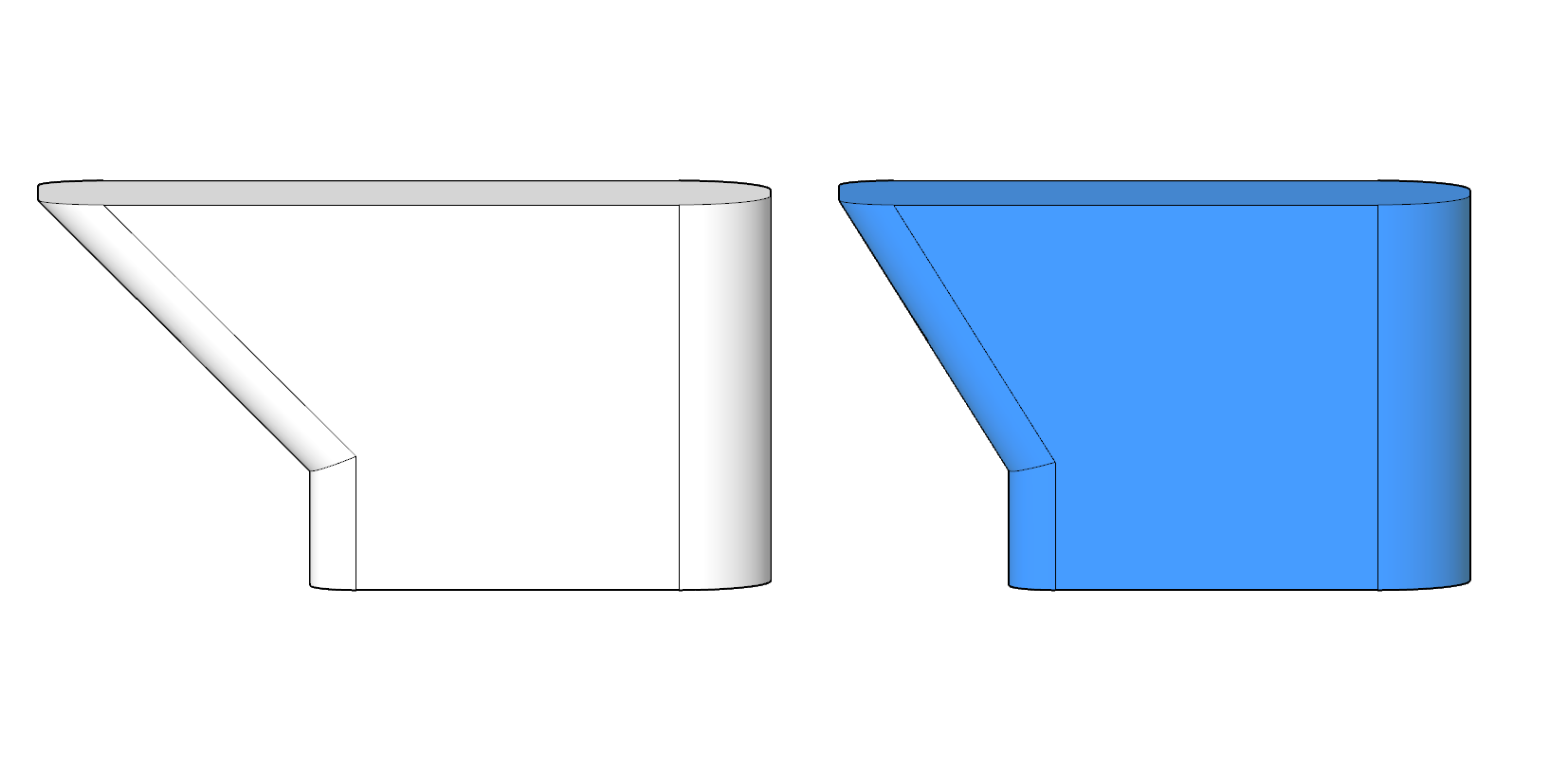

Form Weight Distribution

When designing objects for ceramic printing the impact of gravity & the clay bodies weight must be taken into consideration. Ensure the geometry is self supporting to avoid collapse. This typically means objects have a larger base.

This may mean redesigning your form or splitting the object into multiple sections which can be joined together once printed.

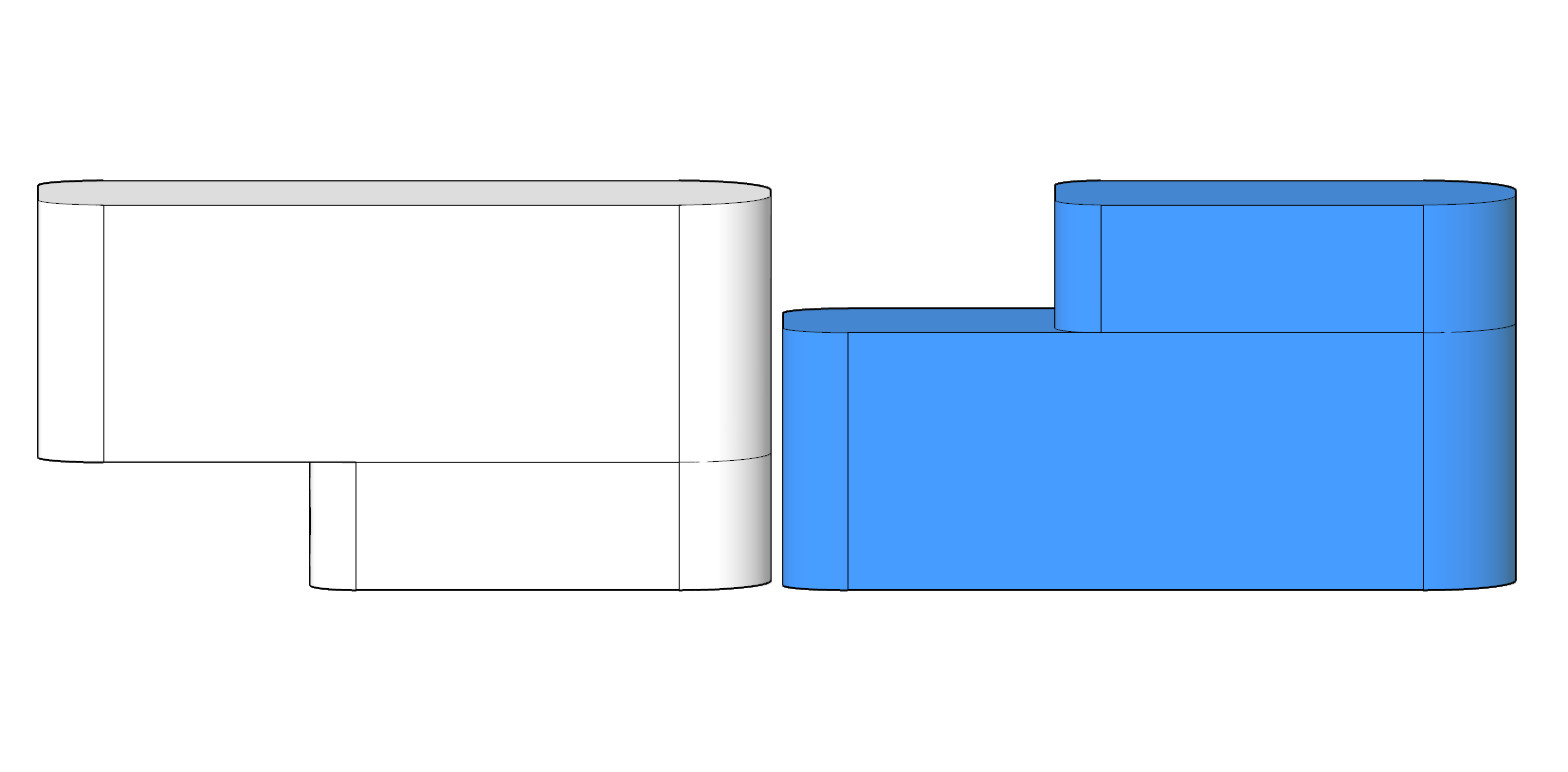

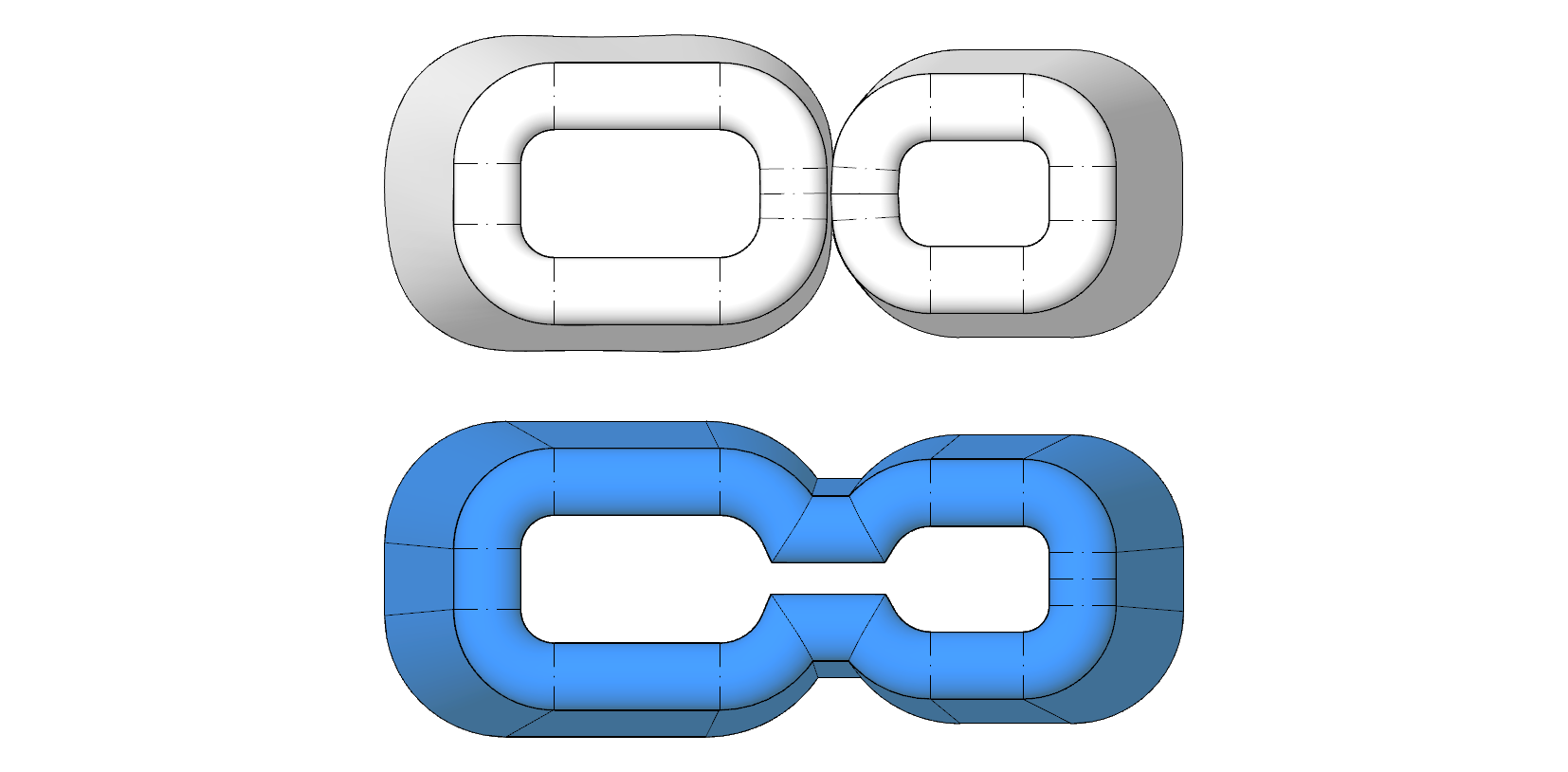

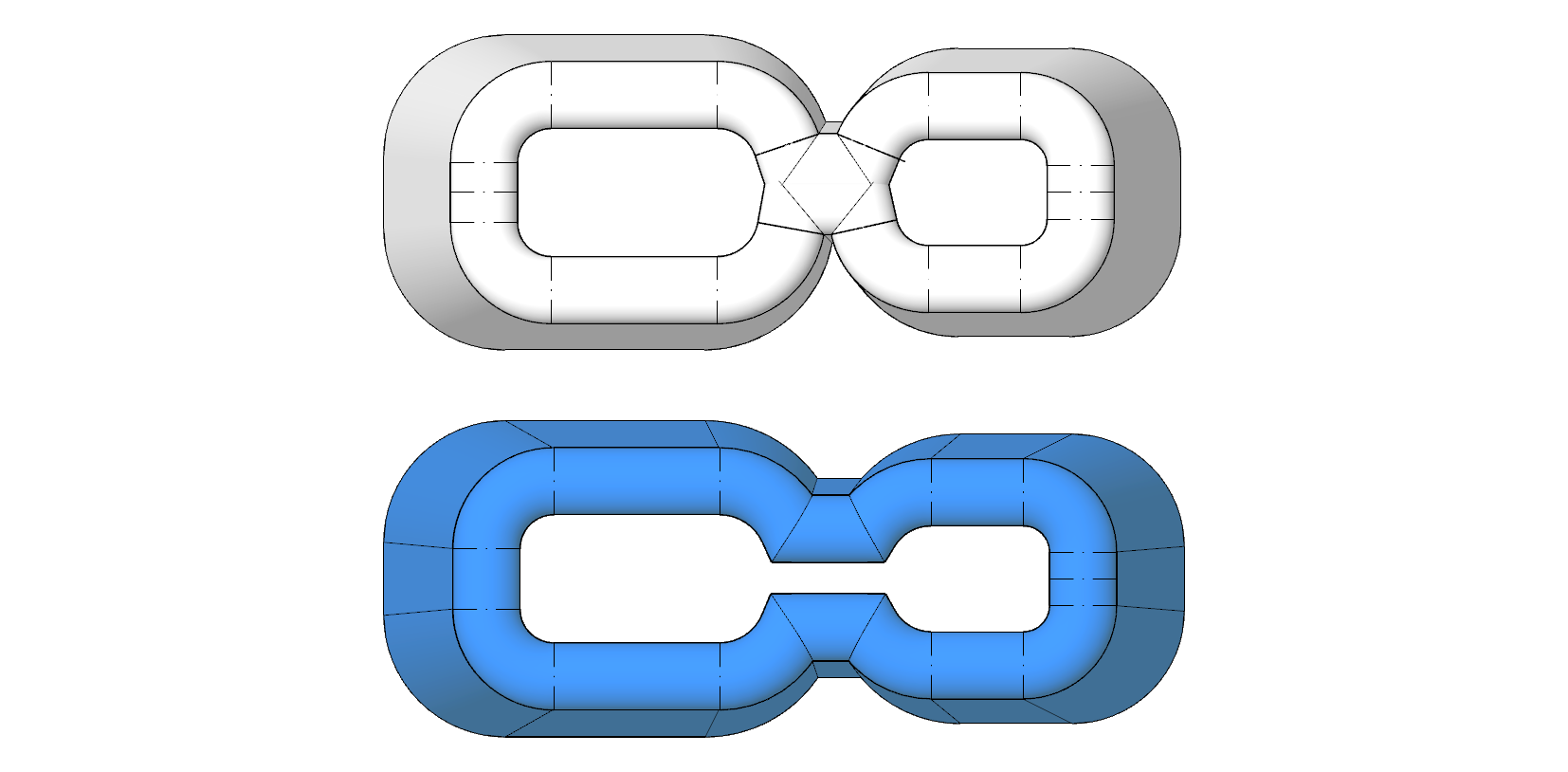

Nozzle Diameter / Extrusion Width

When designing closed forms, models must have a minimum thickness of 2 x the nozzle diameter/extrusion width.

This is to allow the printer to complete the perimeter wall. Failing to do so will result in either;

Last updated