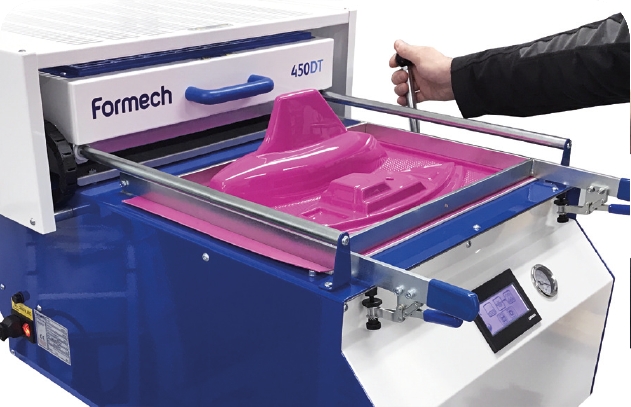

450DT Operation

⚙ this page is under construction ⚙

Before operating the 450DT, ensure you have completed the required training.

If you are unsure, please ask dFab Staff to assist you

Personal Protective Equipment (PPE)

Operation

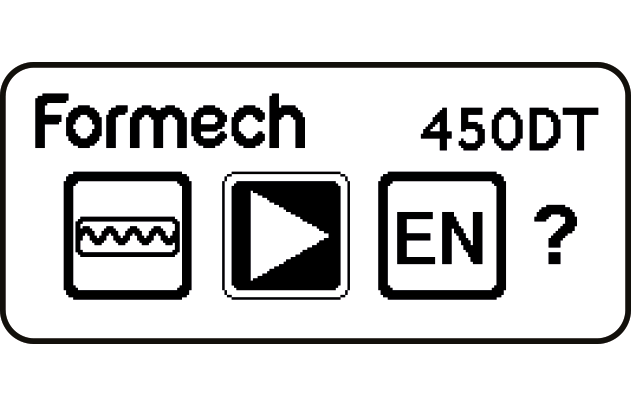

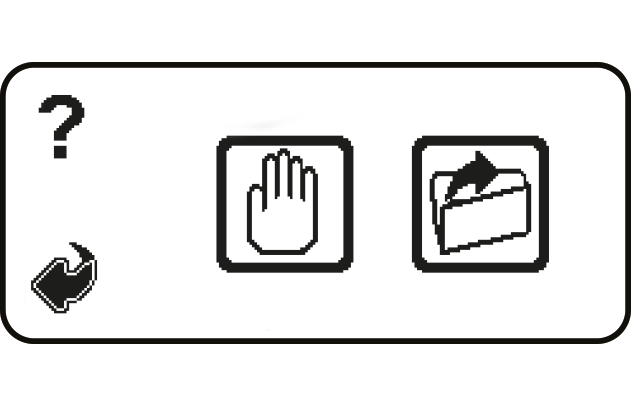

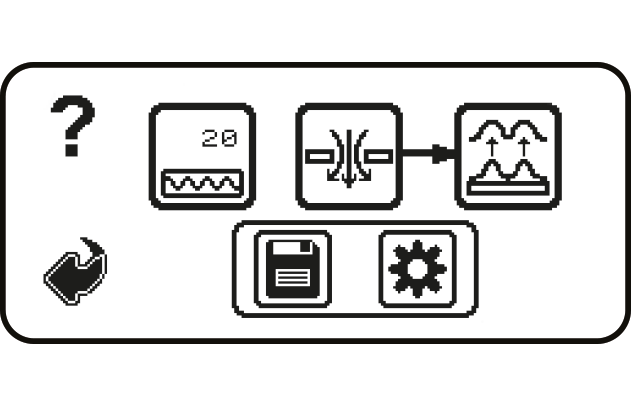

Operation Buttons & Icons can be found below

Turn Machine ON | |

Allow 15 minutes for the machine to reach its operating temperature. | |

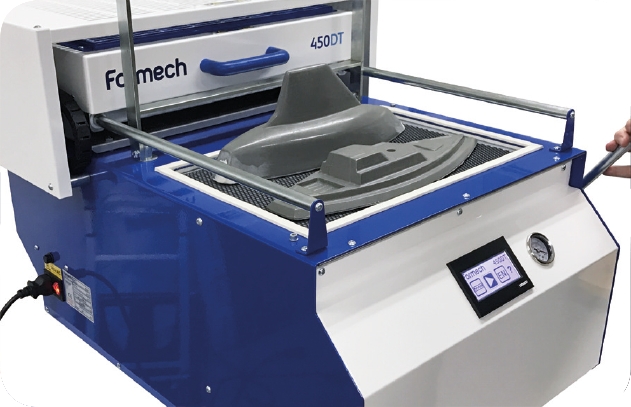

With the heater fully back, raise the table to the top position by pulling the table lever closer to you. | |

Place your mould/s onto the table | |

Lower the table by pushing the table lever away from you. | |

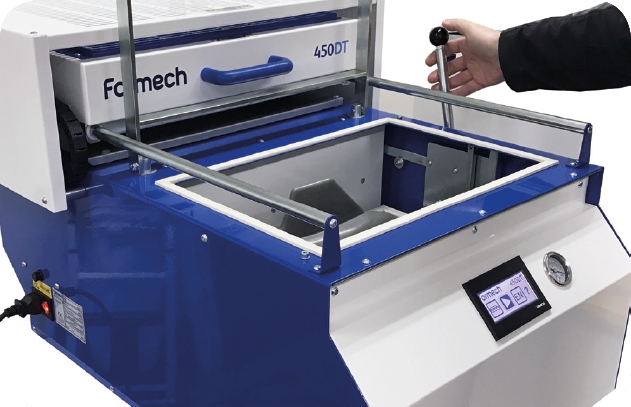

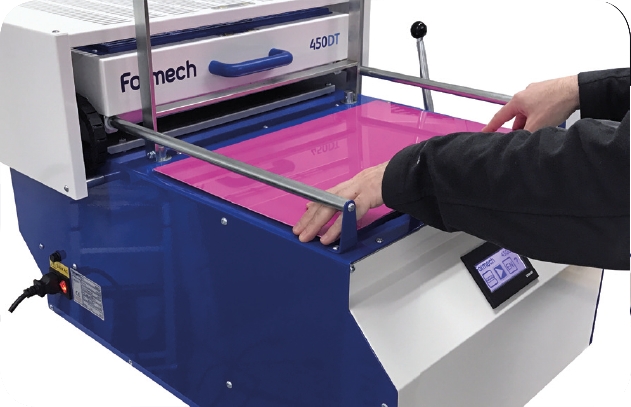

Open the material clamps and raise the clamp frame. Place the plastic material over the aperture | |

Pull the clamp frame down and close the two material clamps. The plastic should completely cover the white seals around the aperture. Adjust the toggle clamp screws to properly grip the plastic. | |

Select the material you are forming with. The operating screen will then open. Two values will show in the heater timer button;

| |

Pull the Heater forwards over the clamped plastic. As the plastic heats up it may begin to rise slightly. It will then soften and begin to drop back. | |

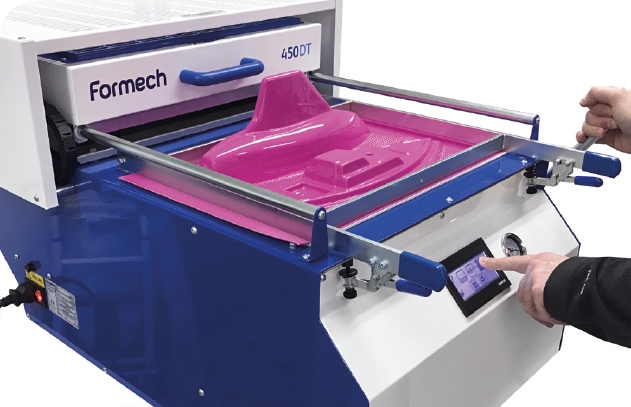

Push the heater back slightly to test the softness of the plastic manually or to observe its state. It is important to check the state of your plastic sheet as environmental conditions will impact how the plastic sheet behaves. Continue heating until it is soft enough to form. When the plastic softness is correct push the heater fully back.

| |

Once released the moulding is now complete and the table may be lowered. | |

Release the clamp frame to remove the moulding for inspection. |

Operation Buttons & Icons

Last updated