Researchers and Teaching Staff engaging digital fabrication support

Executive Summary

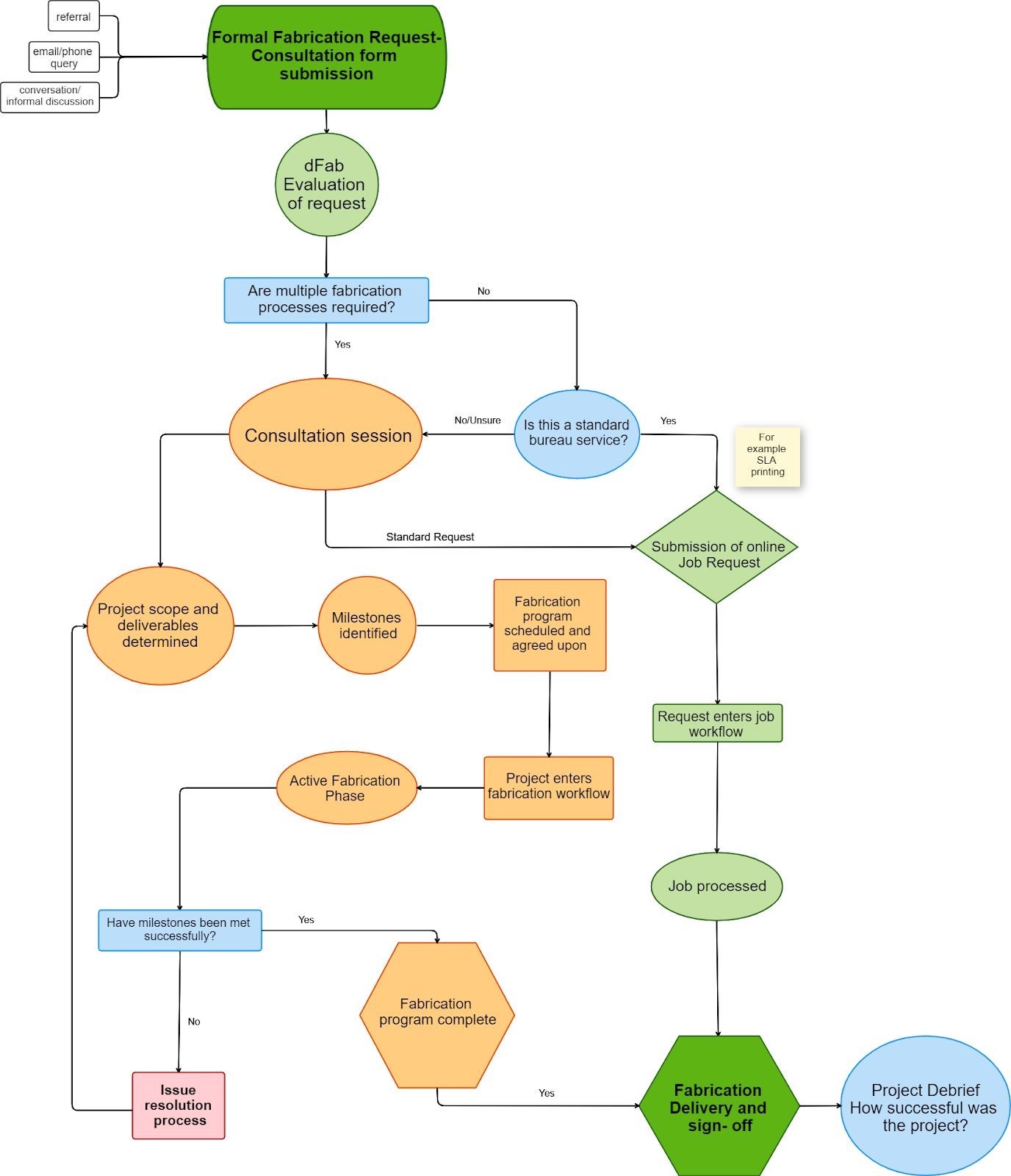

This is the procedure and process for academic staff and researchers to engage technical support for digital fabrication resources and prototyping. The aim is to outline a path, through consultation, for researchers to optimise their use of MADA’s Digital Fabrication Workshop (dFab), in collaboration with the Faculty’s technical expertise. This consultation process enables a formal structure for discussion of the project and defines available technical support. It also sets out the project’s scope and deliverables, including the cost of fabrication to the requestor. From here a fabrication program [Section 6] is developed with measurable milestones, resolution guidelines and other contingencies to mitigate potential issues.

Scope

This procedure applies to individuals or groups within the Faculty of Art Design and Architecture or faculty supported external parties* who are seeking digital fabrication support from the Digital

Fabrication Workshop (dFab) and may include

Research labs

Researchers and Research assistants

Academic staff

Graduate researchers

Procedure Statement

This procedure applies to researchers and technical staff collaborating on the fabrication of physical outcomes, prototypes and experimental fabrication processes related to research projects. It outlines a framework for the steps involved in accessing and providing technical support for research related digital fabrication while facilitating the needs and expectations of all stakeholders. The digital fabrication processes are those that are available within the Digital Fabrication Workshop. This document is accompanied by the dFab Fabrication Support Flow Chart (Appendix A).

1. Procedure aims

1.1. Provide a clear pathway of communication

1.2. Provide a clear guide for researchers to access technical/fabrication support

1.3. Provide technical staff with a process to determine fabrication goals and deliverables as related to a research project

1.4. Allow, through consultation between stakeholders, fabrication workflows and timelines to be developed

1.5. Provide a process for all stakeholders to evaluate the success of the fabrication process

1.6. Outline recommendations for issue/dispute resolution where fabrication goals are not successfully met

2. Communication and consultation

2.1. A researcher initiates a support request by submitting a dFab Consultation Form

2.2. An assessment of the request is made by dFab staff and the need for consultation is determined. In some cases, a simple file submission is all that is required. This will be communicated to the requestor and the relevant information supplied

2.3. Where consultation is required, an introductory meeting is arranged to determine the scope of the research project and to identify the digital fabrication (and other) processes that are required/appropriate

2.4. The consultation process will also be used in identifying and agreeing upon the fabrication deliverables

A program of meetings is scheduled in alignment with the scope of the project and the agreed deliverables

Meetings may occur face to face or via online platforms

Additional meetings may be requested by all stakeholders if the need arises

3. dFab Technical support

3.1. Technical support/advice offered by dFab staff is within the range of the technical team’s knowledge and expertise

3.2. Support and advice, where required, may be given by a range of staff including technical staff from other workshop areas, eg WaM, Hot Workshops

Where possible dFab staff may research and test new technologies/processes with the view of applying them to a research project if the timeline allows

Digital fabrication support is managed by the Digital Fabrication

Workshop Coordinator

All dFab CNC fabrication equipment will be operated by authorised, trained dFab technical staff only. If the research specifically requires it,

e.g. development of new processes, high-risk equipment may be operated by the researcher with training outlined below

In order for a researcher (non-technical staff) to operate high-risk equipment, the researcher must participate in an approved equipment training program and a subsequent period of local induction and training

When operating high-risk equipment, a trained researcher must follow the local procedures for Operating High-Risk Equipment

The fabrication support offered by dFab is dependent on the fabrication equipment and local knowledge available at the time of consultation and the duration of the research project

3.3. Where dFab equipment is unavailable due to operational issues or shortfall in knowledge base alternative arrangements may be sought, eg outsourcing fabrication to third parties

Where appropriate dFab will assist with engaging third party fabrication services

3.4. Technical support/advice will be determined by a holistic approach that takes into consideration; best practice, waste minimisation, appropriate material selection, sustainability concerns and timeline.

4. Fabrication costs

4.1. dFab does not seek to provide service for-profit and therefore does not charge commercial rates for fabrication services. Costs associated with dFab fabrication services are intended to recuperate the cost of materials, consumables, and other outgoings associated with a fabrication project.

dFab can source materials for most fabrication requests

Materials are supplied at cost plus a small margin to cover freight, material handling and processing

The margin has a built-in tool wastage/replacement component

Some processes have a time-based charge added, for example, gas usage in the metal laser cutting process is calculated based on the cutting time required to complete the job

All fabrication work is to be conducted within the normal dFab business hours

4.2. Additional costs may apply to some fabrication projects if the following circumstances are predicted/required

Where a project’s duration is over an extended period of time or engages technical staff beyond a reasonable proportion of their regular duties

Where the fabrication is required to extend outside of dFab regular business hours in order to complete the project

All additional costs are to be discussed with and approved in consultation with the Technical Resources Coordinator and the Faculty Research Office

5. Project Scope and deliverables

5.1. The consultation process enables stakeholders to reach an understanding and specifically define the digital fabrication deliverables required by the research project and also set milestones

Deliverables mark important milestones along a project’s timeline that allow stakeholders to monitor progress and assess metrics

Deliverables allow the assessment of the efficacy of the fabrication process at each specific milestone

At each milestone, it is then possible to re-evaluate the trajectory of the project workflow or the fabrication processes being employed

6. Fabrication Program: workflow and timeline

6.1. A fabrication workflow will be devised in consultation with the researcher by the dFab Technical team to best fit the scope of the fabrication project and the defined deliverables

Where only a single process is required the workflow is determined by that process

Where multiple fabrication processes are required dFab, in consultation with the researcher/s, will develop a complete project workflow

Some research will involve alternate approaches, such as feeding back production into the design process, or feeding back artifact analysis into the production process (see Appendix B for examples of iterative/feedback design workflows). A workflow will be developed in consultation with the researcher.

Once the workflow is determined the fabrication schedule is developed by dFab staff and approved by the researchers/stakeholders

6.2. The fabrication schedule will have a built-in contingency and is influenced by a number of factors;

The level of demand on dFab, its staff and equipment

One of the core functions of dFab is to support undergraduate coursework and the requests generated by those coursework requirements. There may be periods during semester where staff and equipment need to be prioritised for these requirements

Availability of individual technical staff required to carry out specialist fabrication processes or operate specialist fabrication equipment

Maintenance operations or equipment downtime/repair (dFab will endeavor to carry out equipment maintenance work during fallow times of the year)

6.3. Project milestones/deliverables previously identified are worked into the fabrication schedule

Meetings are scheduled appropriately to evaluate the progress of milestones and monitor fabrication progress

7. Contingency and lost time

7.1. Each phase of the fabrication program will include a contingency to allow for unplanned events or circumstances that may impact the fabrication timeline

Unplanned events or circumstances may include machine outage, material supply chain issues, lost time due to illness

7.2. Where unplanned events result in lost time and impacts on the fabrication timeline it is the responsibility of the dFab coordinator to inform all stakeholders

Consultation with stakeholders takes place in order to develop a lost time recovery strategy

Once a lost time recovery strategy is agreed upon appropriate amendments to the fabrication program are made and approved (see section 7)

The new fabrication program is shared with all stakeholders

8. Fabrication commencement

8.1. Prior to the commencement of the fabrication researchers are required to approve (sign off) the fabrication workflow and schedule

8.2. A project cannot commence without this approval

8.3. In addition to approval at the commencement of the project sign off may also be required at nominated milestones

This is particularly important for projects with a long timeline in order to keep them on schedule and keep all stakeholders up to date

Also important when a deliverable needs to go through a validation process, controlled trials or other research-based assessment

8.4. The approved fabrication schedule is shared with all relevant project stakeholders

9. Project completion and project debrief

9.1. Fabrication for a research project is complete and is delivered

when all project deliverables have been met as agreed upon in Section 4 of this procedure

In the event that goals have not been met to the satisfaction of some of the stakeholders a process for resolution will be entered into

9.2. Researchers will be required to ‘sign-off’ at the end of the project to indicate that final goals have been reached

9.3. The sign off will be provided in writing and a record kept by the Digital Fabrication Workshop for further reference. A sign-off form is available to researchers for this purpose (link to document)

9.4. An opportunity for stakeholders to provide feedback during a debrief session. The debrief aims to:

Provide transparency

Provide dFab with feedback on its processes so that it can strive to improve

Provide researchers with feedback in order to streamline processes and reduce double handling

Allow relationships between stakeholders to develop professionally

10. Resolution of unmet goals/targets or disputes

10.1. In the event that goals or targets along the fabrication timeline are not met to the satisfaction of any party as outlined in the agreed fabrication program an Issue.

Resolution process is initiated

The issue resolution process will aim to steer the fabrication process towards the previously agreed deliverables

Where these deliverables are no longer achievable or appropriate new deliverables/goals are identified and agreed upon

A new fabrication timeline is developed and shared with all stakeholders

10.2. The issue resolution process requires stakeholders to meet in order to

Identify the deficiencies/shortfalls in the fabrication outcome/s

Discuss possible strategies for rectifying the shortfalls

Map out an agreed plan of the rectification where all stakeholders’ concerns are considered

10.3. In the event that an issue cannot be resolved an impartial mediator may be brought in to assist with reaching a resolution

An impartial mediator may be a senior academic or professional staff member who has no stake in the project

Definitions

dFab

dFab is Art Design and Architecture’s Digital Fabrication Workshop located on Level 1, Building G Rooms G117 to G125, Caulfield Campus.

Digital fabrication

Digital fabrication is a design and manufacturing workflow where digital data directly drives manufacturing equipment to produce prototypes or finished products or components. Digital fabrication includes additive processes - 3D printing and subtractive processes - CNC milling, laser cutting.

Deliverables

These are quantifiable outputs that are delivered to a client as part of a project at an agreed time.

Milestones

These are important events along the project's timeline that allow the progress of the project to be assessed by all stakeholders.

Appendix A

Last updated